Ek Danta Refiners has for years adopted a more eco-sustainable corporate vision, promoting an industry that respects the environment and a circular economy.

Efficient and zero impact products

Years of experience have taught us how to make our machines more efficient and versatile. Our well-established infrastructure unit is sprawled across a wide land area with various in-house divisions, which helps us in carrying out smooth business process. We have segregated our infrastructure into various divisions like procurement, manufacturing, quality control, R&D, packaging, etc. Our production unit is well-facilitated with all the latest machines and tools, which empower us to design a wide range of products that benefit a number of industrial applications. Moreover, this unit is designed in such a manner that the departments can easily make perfect coordination amongst each other.

E-waste recovery for a cleaner world

Recent study about the rising electronic pollution in the World revealed that the average computer screen has five to eight pounds or more of lead representing 40 percent of all the lead in US landfills. All these toxins are persistent, bioaccumulative toxins (PBTs) that create environmental and health risks when computers are incinerated, put in landfills or melted down. The emission of fumes, gases, and particulate matter into the air, the discharge of liquid waste into water and drainage systems, and the disposal of hazardous wastes contribute to environmental degradation.

The processes of dismantling and disposing of electronic waste in developing countries led to a number of environmental impacts as illustrated in the graphic. Liquid and atmospheric releases end up in bodies of water, groundwater, soil, and air and therefore in land and sea animals – both domesticated and wild, in crops eaten by both animals and humans, and in drinking water.

Ek Danta Refiners has therefore developed specialized innovative technologies for the pyrometallurgical and chemical treatment of WEEE components and for the refining of precious metals and the extraction of the rare earths contained in them. In this way, new raw materials are obtained and waste materials can be disposed of separately.

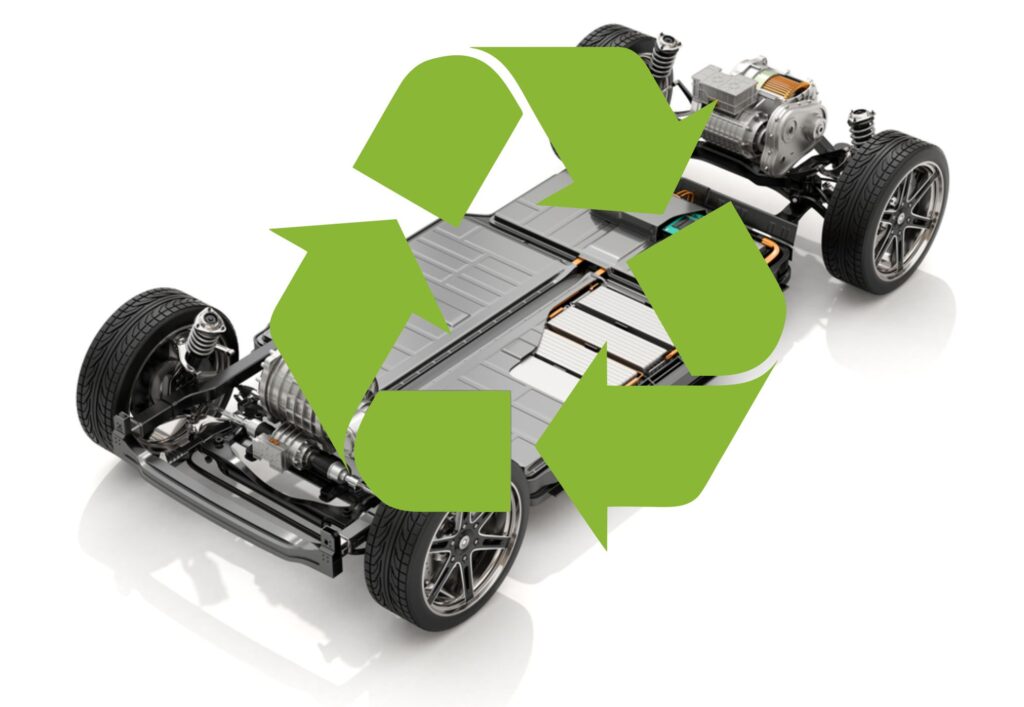

A “Green chemistry” project for the recovery of lithium

Lithium is fundamental in this type of device and is therefore an important element to carry out the technological transformation underway, but world reserves are few and are running out. It is therefore immediately evident how important it is to recover it from batteries already used, together with other equally important materials (eg cobalt, manganese, nickel, copper, aluminum, non-aqueous solvents containing lithium salts).